How to choose the right air compressor hose?

Obtaining a high quality hose (an air compressor one) is fundamental to guarantee stable pressure of air, a tight-sealing and a steady power yield, however, with a tremendous scope of an assortment of hoses accessible available, it very well may be hard to tell where to begin when making your choice. Regardless of whether you’re a home or expert air blower client, you’ll need a reliable air hose to capitalize on your air apparatuses. Ensure the best results when you are looking for rubber hose manufacturers.

When would it be wise to supplant the Air Hose you use?

There are a couple of reasons you’d need to overhaul your hose. The first is you need to update your air framework so you can utilize various apparatuses, or you’re hoping to get increasingly out of your structure. The second is that there’s an imperfection in your current hose and you need to supplant it.

Picking the ideal product:

With various assortments of hoses accessible to purchase, filtering through every one of the options and data can appear to be overwhelming. These extremely just four things you have to choose before you start to buy:

- To what extent you’ll require your hose to run?

- What should the interior width of your hose?

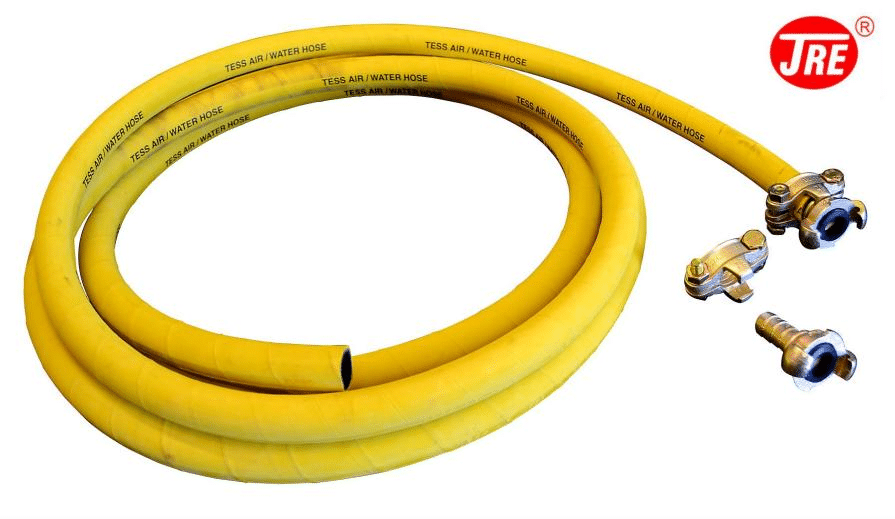

- What is the material used in making of the hose?

- Are you looking for recoil or standard hose?

The Air Hoses’ length:

Your hoses’ length will straightforwardly influence the ease of use and execution of your air devices. You could buy a single tube of fifty-meter length and get to all that you could even require reaching – yet stay away from it! Largeness and cumbersomeness aside, the more drawn out the hose from your blower to your apparatus, the more pressure or air it will lose while in transit. Consider the usage of your air instrument and how a lot of moving you would want from them. For instance, if you need to shower-paint a vehicle in an enormous car shop; you’ll require much more hose for navigating all the way, than for somebody who will utilize an air drilling for making wood-based toys on a work seat.

The point while picking the length of an air hose is to find some harmony between most extreme mobility with your air apparatus and a base pressure loss.

The width of the hose:

The measurement of an air hose is done by their inward distance across. The bigger the internal diameter of the tube, the more air it’ll have the option to convey. While the outer measurement of air hoses will shift relying upon the nature of the tube and the material it’s produced using, regular inside sizes of air hose are six, eight and ten mm inner distance across. Trust professional services when you are looking for rubber hose manufacturers.

The general guideline when picking your hose I.D is the higher the CFM necessity of your air apparatus, the bigger the measurement hose you’ll require. Handheld appliances, for example, shower firearms and nailers will, in general, require one to three CFM and will work impeccably well with a six mm hose. An uncompromising effect wrench is bound to require six CFM+, so you’ll most likely need an eight or ten mm hose to run at full limit.

The width of a hose will influence the general load of the line drastically. Including a few additional millimetres to the hose I.D. before long includes over a separation. For little handheld apparatuses, pick a six mm hose.

What Material Should My Air Hose Be Produced using?

The material your air hose is produced using is going to influence the how adaptable the line is, the heaviness of the line, how it’ll perform and to what extent it’ll last by and large.

Whether Pick a Recoil or Standard Hose:

A recoil hose has loads of little, customary turns, like conventional phone wires. The loops are tractable and have a memory, so when you let go of the hose, it recoils back for simple stockpiling. Picking between the two involves inclination and individual application. For instance, numerous manufacturing plants use to pull back tubes so they’ll spring off the beaten path when not being used. Many splash painters incline toward a standard hose since they don’t care for the obstruction in a wound line.

Pressure drop maintains:

If you have eight-bar leaving your blower, however, the pressure arriving at your device is just 6.5 bar – you’re encountering a drop in pressure. Air hoses are one of the essential drivers of loss in force in a framework and can cause an air device to run inadequately. The air goes through the line and delays the inward coating, creating contact and a drop in pressure.

Conclusion:

The right type of hose has a significant impact in a proper airflow which leads to using them effectively in different applications. Check all the necessary subtleties before picking the proper hose for your use.